Lighter and more compact than alternative packaging options, PET is far less likely to break during transport and requires very little protective packaging material that adds weight, bulk and additional waste.

As a result, PET uses less fossil fuel and energy over the course of the product’s entire lifecycle, not just its production.

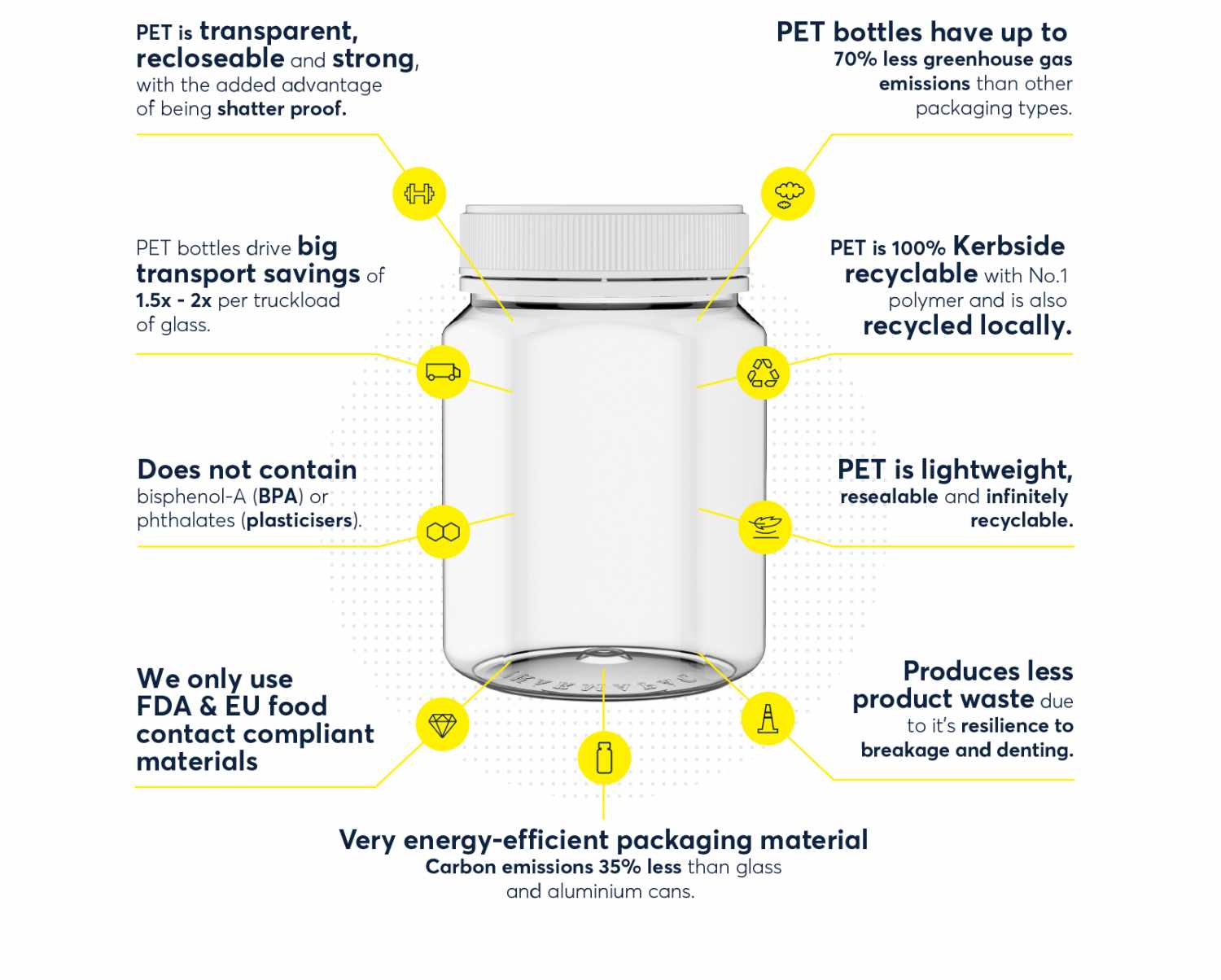

At the end of the day, PET creates fewer greenhouse emissions and less solid waste when compared to glass.

Overall, plastics are lighter and more efficient than many alternatives. Their lighter weight reduces their environmental footprint by decreasing waste, energy use and carbon emissions.

Closing the Loop

Closed-loop recycling is the process by which a product or material is used, recycled and then made into a new product (or converted back to raw material). This can be done indefinitely as long as the product or material doesn’t, during the recycling process, lose its essential properties required for the new product.

Closed-loop recycling minimises sending waste to landfill, reduces our harm to the environment, and discourages resource depletion.

Environmental Facts

Through innovation, the industry is constantly improving its environmental record further. PET plastic bottles have been redesigned so that they are 30% lighter than 15 years ago and increasing amounts of recycled plastic are used to manufacture the bottles themselves.

Its sustainability jumps even higher when recycling is introduced, since approximately 40% of PET's energy use is attributable to its "resource energy" - the energy inherently trapped in its raw materials that can be recaptured and reused through recycling.

Since PET was first synthesised in the 1940s, it has become one of the world's most widely used, versatile and trusted materials.

PET is a very energy-efficient packaging material. Although its raw materials are derived from crude oil and natural gas, it enjoys a very favourable sustainability profile in comparison to glass, aluminium and other container materials.

A tiny proportion of the world’s oil is used to make PET plastic bottles.

- 4% of world oil is used to make all plastic.

- It takes about 25 recycled plastic drink bottles to make one fleece jacket.

- Recycling a tonne of PET containers saves 7.4 cubic yards of landfill space.

- The word plastic comes from the Greek word "plasticos" which means to be shaped or moulded by heat.

At Pharmapac we use a state-of-the-art closed loop water system to promote water usage efficiencies and eliminate water evaporation.